The ingredients used at PK are carefully analyzed for their freshness and are mixed in just the right amount of proportions to give our consumers the taste and aroma for the very best dining experience.

The most optimum measures are taken for retaining the nutritional value of the food so that consumers can enjoy our wholesome meals every time.

1

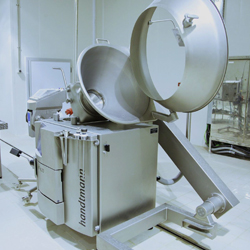

1 2

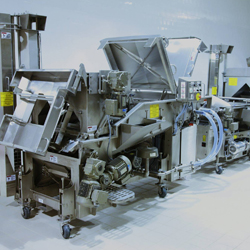

2 3

3 4

4 5

5 6

6